WHAT TECHNOLOGIES DO WE USE?

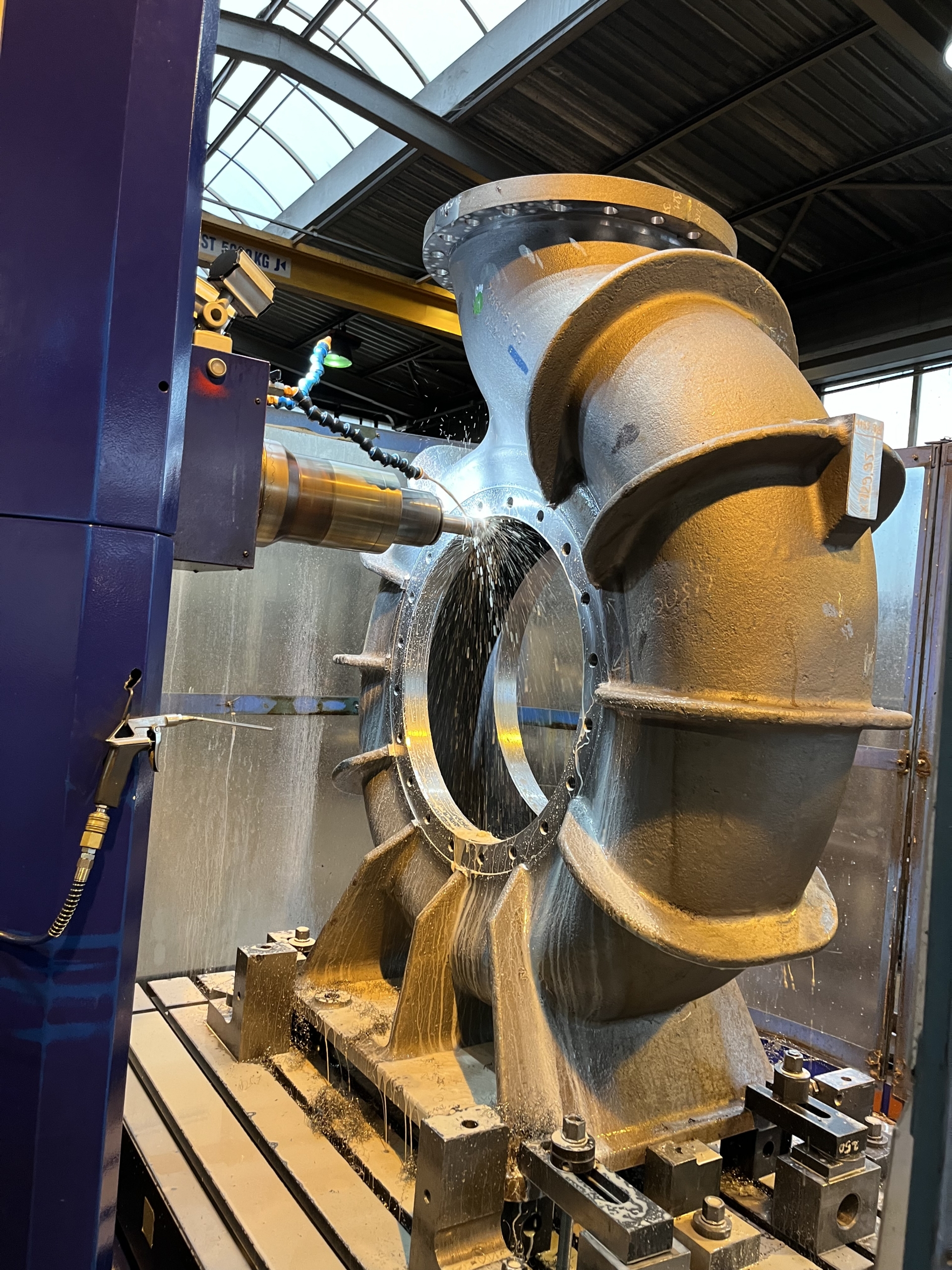

We specialize in custom engineering production. We produce on the basis of drawing documentation supplied by the customer. We are experts in the field of chip machining of weldments, blanks and industrial castings on machine tools. We also do renovations of functional parts of worn machinery and parts, including welding of renovated surfaces. All structural steels are machined with precision to hundredths of a millimeter. Before shipment, each of our workpieces is subject to a strict final inspection in order to avoid possible complaints as much as possible. We only use certified meters that are subject to regular service and metrological calibration. We also take care of our machines in the same way, so that we are still able to maintain the prescribed accuracy of our workpieces.

WORKING

We have CNC desktop horizontal boring machines and a three-axis CNC machining center. The machining hall is insulated, heated and equipped with a bridge crane with a capacity of 5,000 and 3,200 kg.

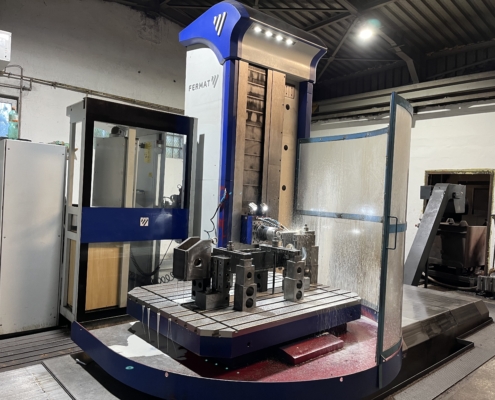

CNC horizontal boring machines

| Machine type | Table clamping surface | Travel in axles (mm) | Spindle extension W | Table load capacity | ||

| (mm) | X | Y | Z | (mm) | (kg) | |

| TOS Varnsdorf WHN13CNC | 2.500 x 1.800 | 3.500 | 2.000 | 1.250 | 800 | 12.000 |

| Fermat WHN13.8CNC | 2.500 x 1.800 | 3.500 | 2.000 | 1.250 | 800 | 12.000 |

| Fermat WFT11CNC |

1.800 x 1.400 | 3.000 | 2.000 | 1.250 | 700 | 8.000 |

| Fermat WFT11CNC |

1.800 x 1.400 | 3.000 | 2.000 | 1.250 | 700 | 8.000 |

CNC machining center

| Machine type | Table clamping surface | Start in axes (mm) | Maximum workpiece height | Table load capacity | ||

| (mm) | X | Y | Z | (mm) | (kg) | |

| STYLE BT1500E | 500 x 1.850 | 1.500 | 650 | 600 | 400 | 1.300 |

Other production options

Other highly specialized partners are concentrated in the RM KOVO industrial area, thanks to which we are able to secure welding capacities for our own production in both black and stainless steel, certified welding supervision and possible assembly of machine subgroups and units. In this way, the entire production is centralized in one area, which speeds up production and minimizes logistics costs.

Thanks to rich cooperation opportunities with high-quality business partners, we also provide blasting, annealing, various types of surface treatments, etc. We are also marginally involved in the sale of metallurgical materials.